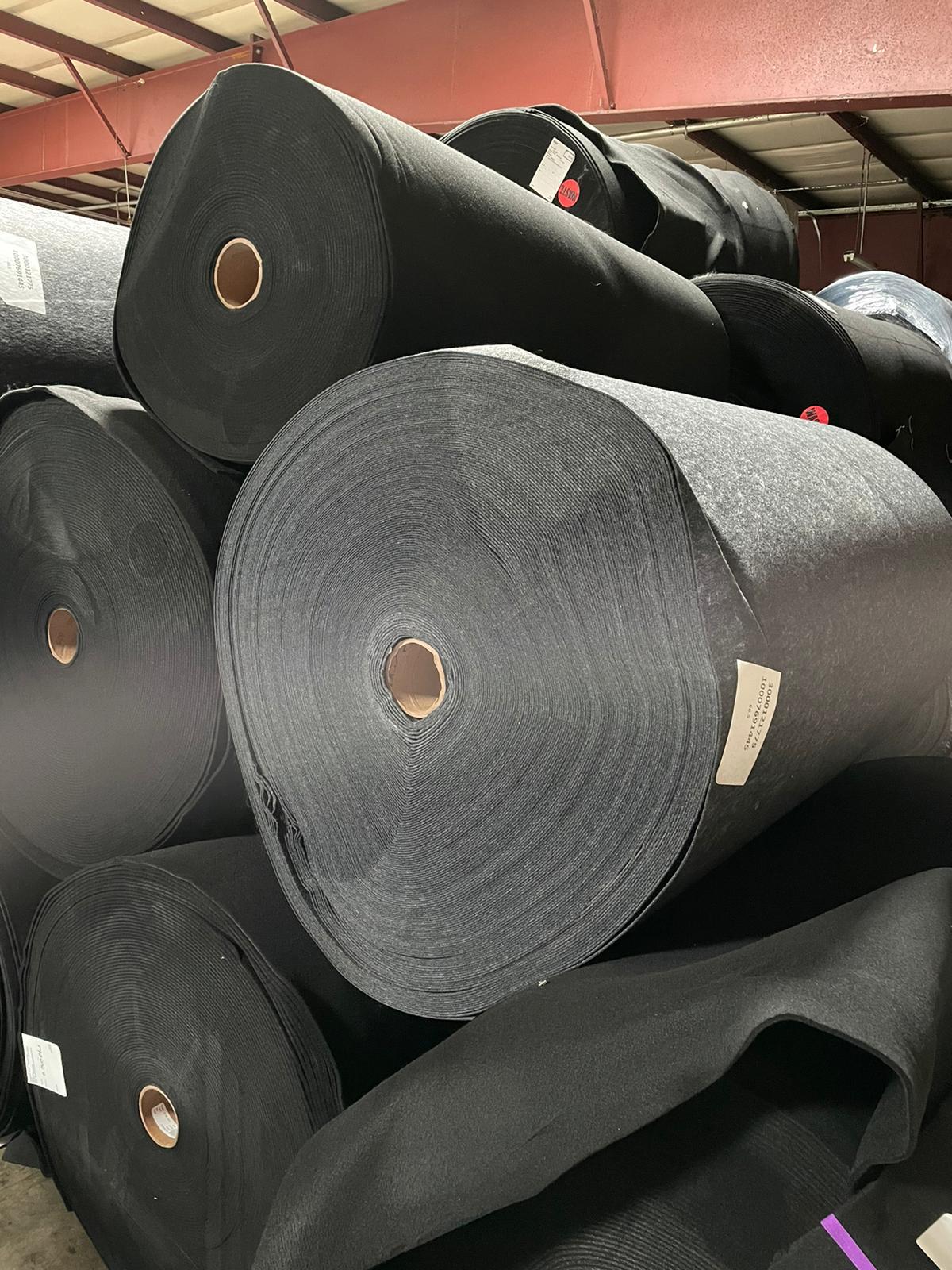

NonWoven Needle Punch Fabric Nonwoven Needle Punch Fabric Latest Price, Manufacturers & Suppliers

Needle punching is one of the methods used for making a nonwoven felt. This involves taking loose fibers and "needling" them together using a needle loom full of barbed needles to force the fiber to push through and entangle itself. It is also one of the types of nonwoven that Bouckaert Industrial Textiles specializes in producing.

ALL STOCK OFFERS GLOBAL STOCKS

The nonwovens created via needle-punching are of size 140 × 35 cm, but for practical purposes the size is 120 × 30 cm because the side of the fabric lacks a needle-punched section. The head sides of the fabric are attached to sewn-together guide fabric and are highly stretched.

Polyester Needle Punch Nonwoven Manufactuer JINHAOCHENG China Huizhou Jinhaocheng

Needle-punched nonwoven fabrics are one of the most commonly used sound absorbing media. For the needle-punched nonwoven fabrics employed for sound insulation, many parameters influence the ability of the fabric to be a good sound absorber, in most cases theeffect of these parameters is studied by varying each parameter individually [1-13].

Best Price on Custom Needle Punch Virgin material needle punched nonwoven fabric felt in roll

Introduction Nonwovens are polymer-based engineered textiles manufactured from a set of randomly distributed fibers consolidated together by thermal, mechanical or chemical techniques.

China Needle Punch Non Woven Fabric for Air Filter China Needle Punch NonWoven Fabric and Non

Needle punched nonwoven fabrics were produced using jute fiber ratio of 5%, 10%, 15%, 20% with 25% kapok, 25% coarse cotton and remaining fine cotton fibers. Oil retention capacities of needle punched nonwoven fabrics were found to be in the range of 7.75 g/g to 16.60 g/g under various process conditions.

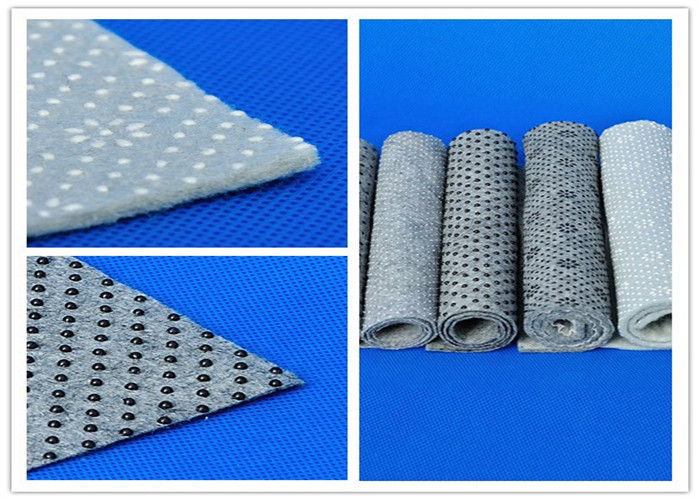

350gsm Needle Punch Nonwoven Ribbed Synthetic Carpet Tiles

It was further asserted that the effect of needle punch is more significant than the penetration depth on the thickness [41]. Additionally, the mass per unit area also plays a crucial role in final performance of the nonwoven and is determined by tailored feeding rate [14, 42, 43].

ProWin and PreNeedleloom PA3000 enhance needlepunched fabrics

Needle-punched nonwoven fabrics Polymer composites Characterization Particulate filler Application 1. Introduction Generally, the reinforcing phase provides the strength and stiffness to the composites. In most of the cases, the reinforcement is harder, stronger, and stiffer than the matrix. The reinforcement is usually fiber or a particulate.

How is needle punch nonwoven fabric formed

All nonwoven fabrics were manufactured using a punching density of 90 punches/cm 2 and punch depth of 8 mm in Dilo needle punching lines with a carding speed of 120 m/min. In all cases of polyester fibers, whether it is round, hollow, or hollow conjugated, the fiber length was maintained at 64 mm. Fig. 2 shows the nonwoven manufacturing process using Dilo needle loom.

Needle Punch Nonwoven China Boting 1 Site For Felt

By including the data from the needle loom (number of strokes, processed nonwoven etc.), the lifetime of each single needle can be traced and analyzed," he says. The leading manufacturer of felting and structuring needles for the nonwovens industry, Groz-Beckert offers more than 2000 different needle types that can be adapted to all possible needlepunch applications.

Polyester Needle Punch Non Woven Fabric Buyers Wholesale Manufacturers, Importers

Needle punch nonwoven are made by entangling fibers with each other using barbed needles. This type of fabric is strong and durable, making it ideal for a wide range of applications. the fabric are made from a variety of materials, including polyester, nylon, and cotton.

Best Sell NeedlePunch Nonwoven Fabric For Shoes Lining Needle Punch Non Woven Fabric Getppes

Needle punching machines, or needle looms, are essential in the production of nonwovens. Nonwovens are mechanically bonded by needling. The needles punch vertically into and out of the material, interlocking the fibers by using the barbs on the needles. The felt is driven through the needle zone by the drive of the feed rollers.

Needle Punch Polyester Nonwoven Hard Felt Roll China Felt and Felt Roll price

Out of different technical textiles, needle-punched nonwoven is one of the promising technical textiles which has wide ranges of applications. This present chapter deals with jute and synthetic fibre-based needle-punched nonwoven. The design and manufacturing of such nonwoven and proper characterization of the developed fabrics based on the end use has been covered. Jute and jute-based.

Needle Punch Nonwoven Geotextile Pioneer Technical Textile(Jiangsu) Co.,Ltd.

Needle Punch Nonwoven Fabric (also referred to as Needlefelt) is exactly that - fabric that is bonded together by needling. This form of bonding provides a great deal of flexibility and, as a result, such fabrics can be designed to offer high levels of strength and integrity or to be soft and very loosely bonded.

Nonwoven Needle Punch Felt Manufacturer in Gujarat India by Savia Felt Pvt. Ltd ID 3119564

The influence of process parameters including punch frequency, needle penetration depth and punch times on the ber distribution and straight segment ber length of needle punched nonwovens was. fi fi. investigated using the Hough transform method. The results show that punch frequency and punch times have more signicant inuence on the samples.

PET Needle Punch Nonwoven at Rs 150/kg Dadar East Mumbai ID 8462245130

As shown in Table 3, with a high interlocking of fiber, needle punch density of nonwoven fabrics is high in 550 g/m 2 to 90 leading to decrease in the tearing strength.-Tensile properties: A.

needle punch nonwoven Needle Punched Non Woven Fabric Ming Yu

The needle-punched non-woven fabric was prepared from three different types of cross-section polyester fibres, regular, hollow and trilobal. The fabric samples were produced at four different.